The Project

The “European Green Deal” provides a roadmap and an ambitious package of measures for creating a sustainable and green European economy, with zero net emissions by 2050. The latter provides “a future-oriented agenda for achieving a cleaner and competitive Europe in co-creation with economic actors, consumers, citizens and civil society organisations.” The INN-PRESSME Open Innovated Test Bed (OITB) provides a twofold approach to support European companies in reaching the ambitious objectives:

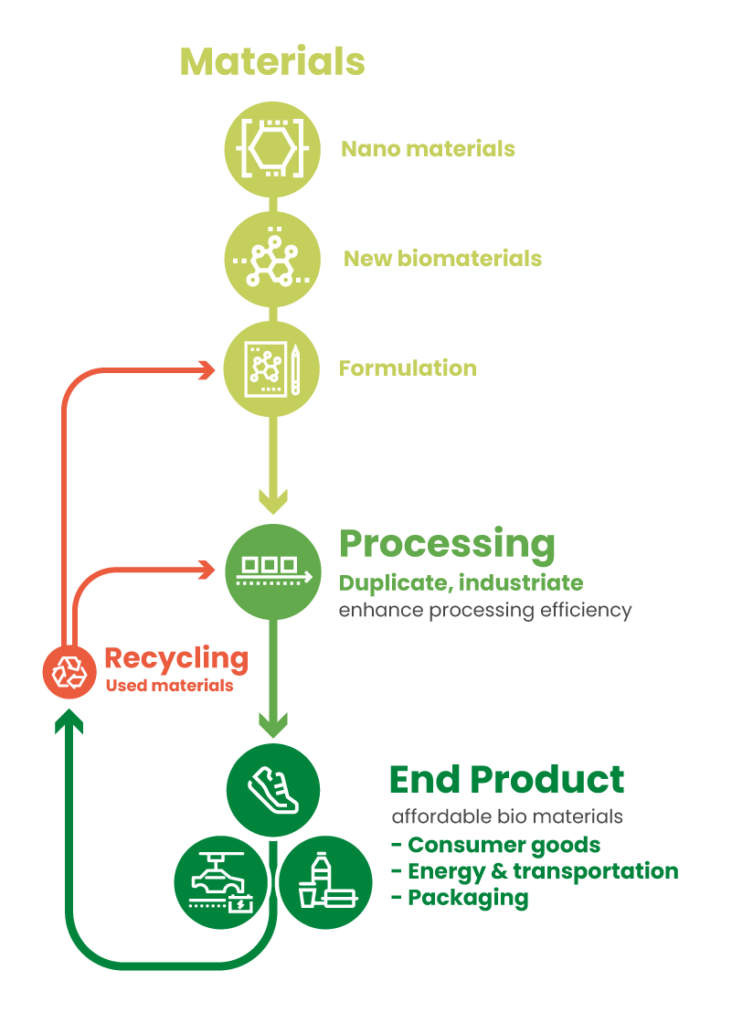

- Developing new market-ready products and goods, from bio-based materials, by feedstock conversion. Nano-enabling will make these materials reach and exceed performances of current fossil-based materials. All materials at TRL7 will be environment-friendly according to circular economy principles.

- Support the digital transition by providing companies with all data and life cycle value chain modelling tools, compatible with an industrial production move to TRL9, from feedstock conversion to material processing. This is key in maximising the use of feedstock materials in the circular economy.

Major INN-PRESSME Milestones

2021

- Project start

- Pilot lines begin

- Development of the OITB and INN-PRESSME ecosystem

2022

- Pilot lines developed

- Demo cases begin

- Further development of the OITB and INN-PRESSME ecosystem

2023

- Demonstration of test cases completed

- “Open Call” launched and new test cases selected

- Development and implementation of the OITB and INN-PRESSME ecosystem

2024

- Implementation of the additional "Open Call" test cases of the OITB and INN-PRESSME ecosystem

What is an OITB - Open Innovation Test Bed ?

An Open Innovation Test Bed (OITB) is a set of entities, providing common access to physical facilities, capabilities and services required for the development, testing and upscaling of nanotechnology and advanced materials in industrial environments.

The objective of the Open Innovation Test Beds is to bring nanotechnologies and advanced materials within the reach of companies and users to advance from validation in a laboratory (TRL 4) to prototypes in industrial environments (TRL 7).

Open Innovation Test Beds will upgrade existing, and support establishing, public and private test beds and pilot lines to develop, test and upscale nanotechnologies and advanced materials for new innovative products and services in specific domains.

INN-PRESSME OITB will tackle the challenges by associating all competences for SMEs and companies in one place, allowing them to get access to bio-based materials with enhanced properties, mainly by incorporating nano additives, while covering the whole value chain with 16 Pilot Lines (from feedstock conversion to final end products), and with circularity and sustainability as essential drivers.

This will serve to ensure competitive end-prices of nano-enabled bio-based materials and reduced time-to-market, taking into consideration regulations and supply chains’ requirements, and offering multiple useful services to companies such as business support and access to funding.

Key Innovations in the Pilot Lines

The INN-PRESSME Open Innovation Test Bed is backed by a network of 16 Pilot Lines established across Europe (Spain, France, Finland, Sweden, Germany and Poland). The Pilot Lines will be upgraded during the project.

INN-PRESSME Applications

A set of 9 test-cases will be used to validate the improved materials’ performances and functionalities of the solutions developed by INN-PRESSME at real scale testing, and demonstrate the expected impacts, mainly those related to circularity.

Explore our pilot lines

INN-PRESSME will develop

state of the art bio-materials

Nano materials

Nanomaterials describe, in principle, materials of which a single unit small sized (in at least one dimension) between 1 and 100 nm.

Bio-Based materials

The use of bio-based materials from biological sources (e.g. plants) as sustainable alternatives to fossil-based counter parts is growing in the packaging, transport, and consumer goods sectors.

End materials

The project aims to provide a network of pilots that cover all the value chain ensuring access to scale-up projects.

Packaging

By 2030, all plastic packaging placed on the market in the EU should either be reusable or can be recycled cost-effectively.

Energy & Transport

Up to a quarter of the mass of a modern mid-size car, which is about 1 100 kilograms, consists of polymer materials today.

Consumer Goods

A shoe sole, made of sustainable materials, is one of two products that the INN-PRESSME project is developing for the end consumers.