Europe sees a new drive to take bio-based materials from lab benches to mainstream packaging, cars and consumer goods. The goal is to reduce the dependency on oil-based materials and advance a circular economy as prices rocket and the world commits to curbing plastic waste

Editor: Gloria Pallares

Across Europe, facilities like the VTT Technical Research Center of Finland are racing to develop and bring to scale affordable, performant alternatives to fossil-based plastics. They are using sources such as agricultural and forestry waste, or harnessing fungi and marine bacteria as living factories of chemicals for the products of the future.

Since the 1950s, the world has produced an estimated 9.2bn tonnes of plastics, of which 7bn are now waste that will take between 20 and 500 years to decompose. Most of that waste is incinerated, resulting in carbon emissions that worsen global heating. Biodegradable materials could replace conventional plastics and advance a zero-waste economy, but they need to overcome some obstacles first, such as price.

To speed up progress, 27 research institutes and partner companies from nine European countries have teamed up under the EU-funded INN-PRESSME project. They are sharing facilities and expertise to take new-generation materials from lab benches through pilot lines to the large-scale industrial processes of companies producing anything from cars, shoe soles and tubes for cosmetics to foam boxes, printable inks and smart labels for food.

“Bio-based materials can reduce Europe’s dependency on oil and speed up the transition towards a circular, waste-free economy, ” says scientist Ulla Forsström from VTT, which coordinates the initiative. “By joining forces, we can improve, test and bring innovative solutions to the market, faster and with fewer risks.”

FROM NANOPARTICLES TO MASS PRODUCTION

A first objective is to enhance the properties of innovative materials to match, and even surpass, the features that made fossil-based plastics an essential component of daily lives: durability, strength, lightness – and affordable prices.

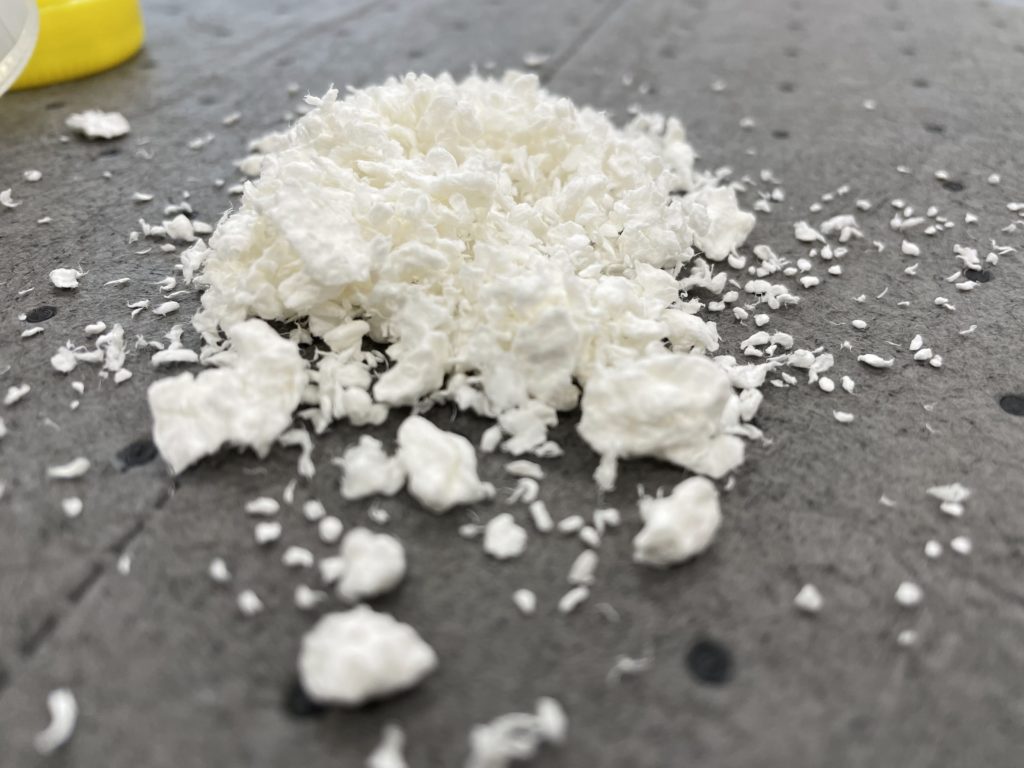

Scientists are fine-tuning formulations and harnessing tiny particles of natural origin – cellulose nanofibrils and nanocrystals, graphene and carbon-based spheres – to enhance the properties of materials sourced from biomass. What those nanoparticles have in common is their size (smaller than 100 nanometres).

“For example, we can combine tiny flax or hemp fibers with bio-based materials to create alternatives to oil-based polymers that can be extensively reused and recycled,” says expert Christoph Mack from the Fraunhofer Institute for Chemical Technology in Germany.

The next step is adapting industrial processing methods to produce bio-based materials on a large scale, taking into account each part of the supply chain from raw materials to end product. The EU-funded initiative is running nine test cases, and later this year, will launch an open call to support small and medium-sized companies in piloting their innovations.

TURNING BIO-WASTE TO VALUE

One of the test cases underway, at VTT in Finland, is looking into alternatives to plastic films and even cellophane, whose manufacturing requires polluting chemicals such as carbon disulfide.

The research center is using waste from pulp mills as well as paper- and textile-recycling plants to create regenerated cellulose film. It is transparent, biodegradable and water resistant, and can be used as stand-alone or as a coating for paper.

VTT scientist Vesa Kunnari notes that the pilot line is modular, making it easier, quicker and cheaper to test different source materials: “For example, the side streams of a food manufacturing process could be used to create packaging for the food itself.”

The equipment sits next to a surface-treatment pilot line, which companies can use to test new foam, spray and road-coating solutions for packaging, flexible electronics and non-wovens. “Importantly, they can do it using only small amounts of material, which is essential to keep costs down,” says VTT expert Vinay Kumar, who mentions applications in the medical, chemical and textile industries.

Another product that experts are looking to take to the next level are transport boxes made from bio-foam beads. “Like the ones food delivery services use to keep your pizza warm,” says Mack from the Fraunhofer Institute.

Mack’s team is working to reinforce bio-based beads with natural fibers and anti-microbial coatings, then produce expandable granules “comparable to popcorn” that can be molded into 3D objects. For example, impact-proof, insulating containers and sports goods such as balancing boards and fascia rolls.

“The ultimate goal is to replace oil-based materials with fully reusable, recyclable and biodegradable alternatives that result from sustainably-sourced biological materials and processes,” says Mack. “Materials that make sense from both an environmental and an economic perspective.”