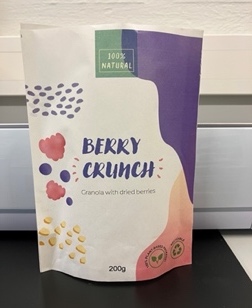

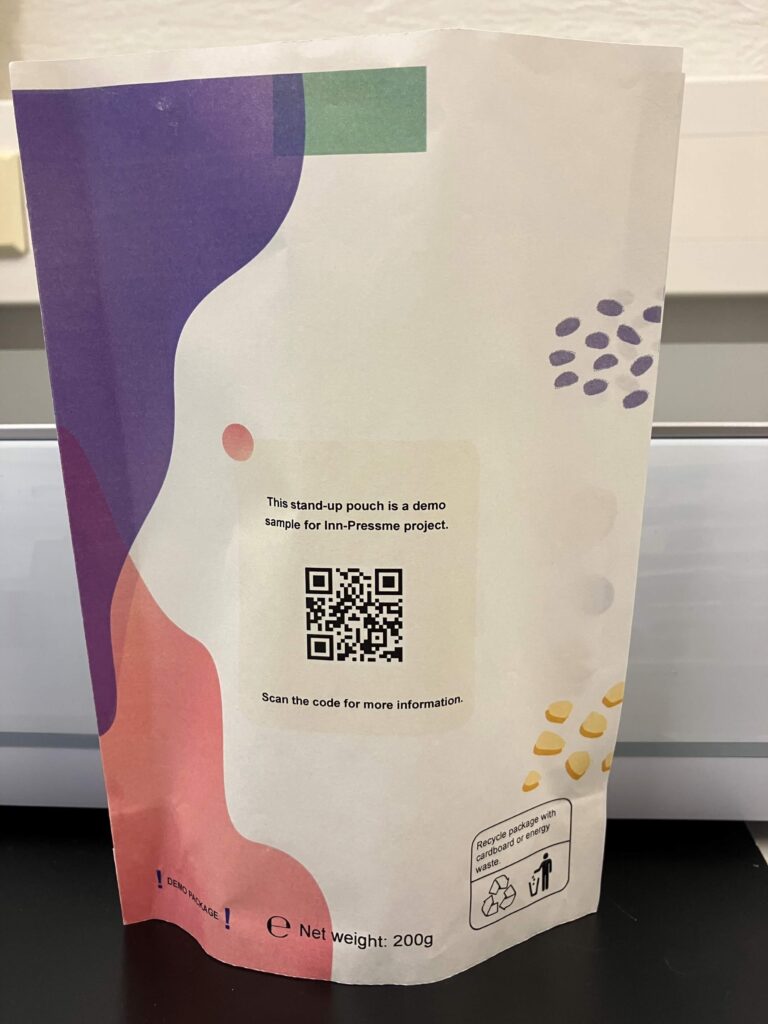

The food packaging market is the focus of research and development by INN-PRESSME’s Finnish partner VTT. Food packaging, which protects against external influences such as moisture and light, is still mainly produced from numerous non-sustainable fossil materials. Multiple layers of plastics or metals make it impossible to recycle or biodegrade them. As part of the INN-PRESSME project, Finnish researchers and developers have further developed the production of stand-up pouches using biological nanofibres. The aim is to replace all fossil materials in the packaging and produce it in such a way that it can be easily recycled.

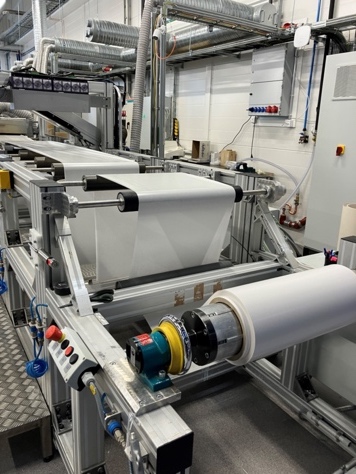

Together with the INN-PRESSME partners WALKI, FRAUNHOFER ISC and RISE, they ensure production safety and the requirements of industrial production sizes. The SUTCO coating machine specially developed by VTT took the team a big step forward. The SUTCO process has so far been used to test PLA-X, cellulose nanocrystals (CNC) biobased hybrid nanomaterials on thin paper. In the so-called thin-film coating processes, the results indicate that the industrial quantities can be achieved.

Facts & Figures

- Multilayer coating done on two different base papers using:

- PLA-X (crosslinkable PLA-based aqueous dispersion)

- CNC (cellulose nanocrystals)

- bioORMOCER® (biodegradable inorganic nanoparticles stabilized by biopolymers )

- Traditional coating methods such as gravure coating can be used to apply these materials into multilayer structures

- Low coat weight and coating thickness (below 12 g/m2 and 8 µm) for all three layers combined

- Promising barrier properties at 23 °C/ 50% RH

- OTR as low as 0.8 – 2 cc/(m2.day.bar)

- Excellent grease and mineral oil barrier

- Good heat-sealing properties