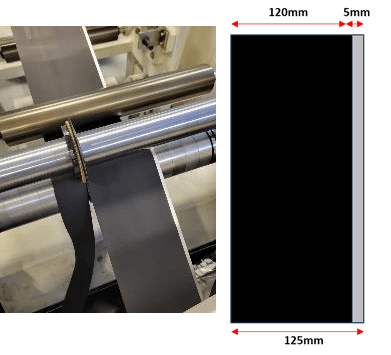

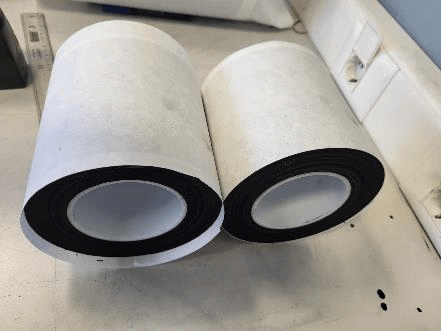

Partners developed bio-based ultracapacitors fabricated from high energy density electrodes, prepared by roll-to-roll coating of water-processed slurries comprising carbonaceous composites of biological origin and green nanocellulose binders.

Facts & Figures

- Successful production of electrodes using binders from biomaterials.

- Still further optimization is needed to completely eliminate binders; achieved a 75% reduction in SBR (from 4% to 1%).

- Industrial-scale production of demonstrators with a standard and high-capacity format.

- The final result is acceptable (80% of the capacity of the standard and optimized supercapacitor), but better values could have been achieved by fine-tuning the final particle size and optimization of the electrode coating process. This would have influenced adhesion, electrochemical properties, and the proportion of binders required.

- Future exploration could focus on testing these biomaterials, especially the binders, for potential use in batteries, particularly in lithium-ion technology.