The aim of the INN-PRESSME Open Innovation Test Bed is to develop services along the entire value chain to help the industry integrate sustainable biomaterials into its processes. INN-PRESSME is supporting European SMEs and companies to develop bio-based solutions in the packaging, energy, transport, and consumer goods sectors.

On the real test bench, nine test cases are used to validate the performance of the improved materials. Their expected impacts will be demonstrated, with emphasis on circularity. All new bio-material developments, formulations and processes are tested in 9 real application cases.

Four test cases coordinated by VTT are targeting the packaging sector:

• Bio-based adhesive smart labels for food and cosmetics

The bio-based adhesive smart label will be fabricated on a paper substrate produced by Arjowiggins and will consist of a RFID communication system (Antenna + programmed chip with an internal temperature sensor), a printed electrochromic display, a printed battery, and a printed humidity sensor.

Large batches of the electrolyte formulations are developed for the display and the battery. A printed humidity sensor in sheet-to-sheet configuration is optimised before transferring it to industrial partners, Arjowiggins and SKANEM.

• Fibre-based heat-sealable stand-up pouches with high barrier performance

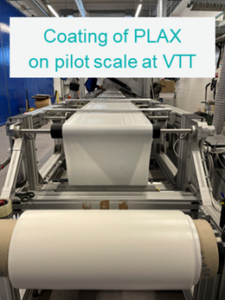

In this test case, different INN-PRESSME partners will collaborate to develop a bio and fibre-based stand-up pouch. The target is to produce a packaging solution with a high renewable content (~100%) by using a PLAX dispersion coating layer combined with a lacquer layer of bio-based hybrid nanomaterials.

In this test case, different INN-PRESSME partners will collaborate to develop a bio and fibre-based stand-up pouch. The target is to produce a packaging solution with a high renewable content (~100%) by using a PLAX dispersion coating layer combined with a lacquer layer of bio-based hybrid nanomaterials.

PLAX dispersions are produced with a thermomechanical method. PLAX formulations are stabilised and coated in pilot scale with a suitable coating method on pre-coated substrates provided by the end-user WALKI. The production of bioORMOCER® lacquers are up scaled and will be applied via existing dispersion coating methods on the PLAX coated substrates. The bio-based stand-up pouch produced in this test case will represent an easily recyclable packaging solution for high-end barrier applications.

• Bio-based boxes replacing the current material with bio-foam

A bio-based alternative for transportation boxes made from bead foams shall be developed. Polymers from renewable resources will be reinforced with natural microfibres via compounding to increase the thermo-mechanical properties of the material.

These compounds will then be used to develop bead foams via extrusion of gas-loaded granules and subsequent pre-foaming and 3D-printing filaments. The foamed beads will be moulded by the end-user WSVK to a transport box. The bio-based box shall show the use of bio-based materials in demanding applications to substitute fossil-based products.

• Bio-based tubes for cosmetics with focus on laminated structures

INN-PRESSME targets the development of bio-based tubes for cosmetics, a fully recyclable packaging solution made of 100% bio-based materials like polyhydroxyalcanoate (PHA). The tube shall have high gas barrier properties obtained through the novel multi-nanolayering technology. In addition, aesthetics will be achieved by environmentally friendly bioORMOCER® coating solutions. The new design will be based on three-laminated layers:

- an outer bio-based plastic film with environmentally friendly lacquer to provide aesthetics

- a central paper sheet

- and an inner multi-nanolayered film

Three test cases for energy and transport are developed by CIDETEC:

• Bio-based automotive components with nano-enabled functionalities

This test case targets the development of functional bio-based automotive components fabricated by 3D printing. Nano-enabled bio-based polymers will be processed by additive manufacturing 3D printers to produce different prototypes of recyclable car parts such as door handle, central console or dashboard fascia, with antimicrobial and aesthetic (odour capture, fragrance release) properties and improved thermal and mechanical performance, to be validated by the end user CRF-FIAT.

This test case targets the development of functional bio-based automotive components fabricated by 3D printing. Nano-enabled bio-based polymers will be processed by additive manufacturing 3D printers to produce different prototypes of recyclable car parts such as door handle, central console or dashboard fascia, with antimicrobial and aesthetic (odour capture, fragrance release) properties and improved thermal and mechanical performance, to be validated by the end user CRF-FIAT.

• Bio-based automotive parts as structural/ aesthetic components

Bio-based structural/aesthetic car components will be developed, specifically recyclable car side pillars produced by 1K-injection moulding of bio-thermoplastics incorporating natural fibres. Subsequent deposition of a nano-enabled biodegradable sol-gel coating will impart the injected part with optimal aesthetic properties, to be validated by the end user MAIER.

Bio-based structural/aesthetic car components will be developed, specifically recyclable car side pillars produced by 1K-injection moulding of bio-thermoplastics incorporating natural fibres. Subsequent deposition of a nano-enabled biodegradable sol-gel coating will impart the injected part with optimal aesthetic properties, to be validated by the end user MAIER.

• Bio-based ultracapacitors

The bio-based ultracapacitors will be fabricated from high energy density electrodes prepared by roll-to-roll (R2R) coating of water-processed slurries, comprising carbonaceous composites of biological origin and green nanocellulose binders on a current collector. End-user SKELETON will prepare industrial-sized ultracapacitor cells with the optimal electrodes based on bio-carbons and cellulose and evaluate them according to industrial standards for capacitance, equivalent series resistance and behaviour in lifetime.

The bio-based ultracapacitors will be fabricated from high energy density electrodes prepared by roll-to-roll (R2R) coating of water-processed slurries, comprising carbonaceous composites of biological origin and green nanocellulose binders on a current collector. End-user SKELETON will prepare industrial-sized ultracapacitor cells with the optimal electrodes based on bio-carbons and cellulose and evaluate them according to industrial standards for capacitance, equivalent series resistance and behaviour in lifetime.

Two test cases focusing on consumer goods are led by FRAUNHOFER ICT:

- Fully bio-based fungicidal complete footwear with superior performance and wear resistance

This test case targets the development of bio-based fungicide inner shoe soles, validating the application of sustainable nano-enabled bio-based materials in therapeutic shoe soles with personalized functionalities such as antimicrobial, antiodour and durability processed by 3D printing. Different partners will collaborate to develop the bio-based fungicide inner shoe soles.

This test case targets the development of bio-based fungicide inner shoe soles, validating the application of sustainable nano-enabled bio-based materials in therapeutic shoe soles with personalized functionalities such as antimicrobial, antiodour and durability processed by 3D printing. Different partners will collaborate to develop the bio-based fungicide inner shoe soles.

Natural microfibres are produced to improve compatibility and proper fibre distribution in the biopolymer.

The formulations will be prepared by extrusion compounding and delivered to extrude filaments for 3D printing. The TPU reinforced filaments are processed by 3D printers to manufacture shoe shole demonstrators, implementing plasma and hot press activation between layers to enhance properties.

Customized shoe soles with fungicide functionality are designed and produced based on a multitude of parameters (weight, tread pattern, injuries, etc.). Selected demonstrators will be validated by Podoactiva with real patients that will give their experience and feedback.

- Bio-based sporting goods, replacement of current material with bio-foam with high mechanical strength and antimicrobial properties

A bio-based alternative for sports goods like fascia rolls made from bead foams will be produced. Polymers from renewable resources will be reinforced with natural fibres via compounding to increase the thermo-mechanical properties of the material. These compounds will then be used to develop bead foams via extrusion of gas-loaded granules and subsequent pre-foaming.

The foamed beads will be moulded by the end-user WSVK e.g. to a fascia roll. An antimicrobial coating shall protect the bio-based foam from degradation through microorganisms. The bio-based product shall show the use of bio-based materials in demanding applications to substitute fossil-based products.